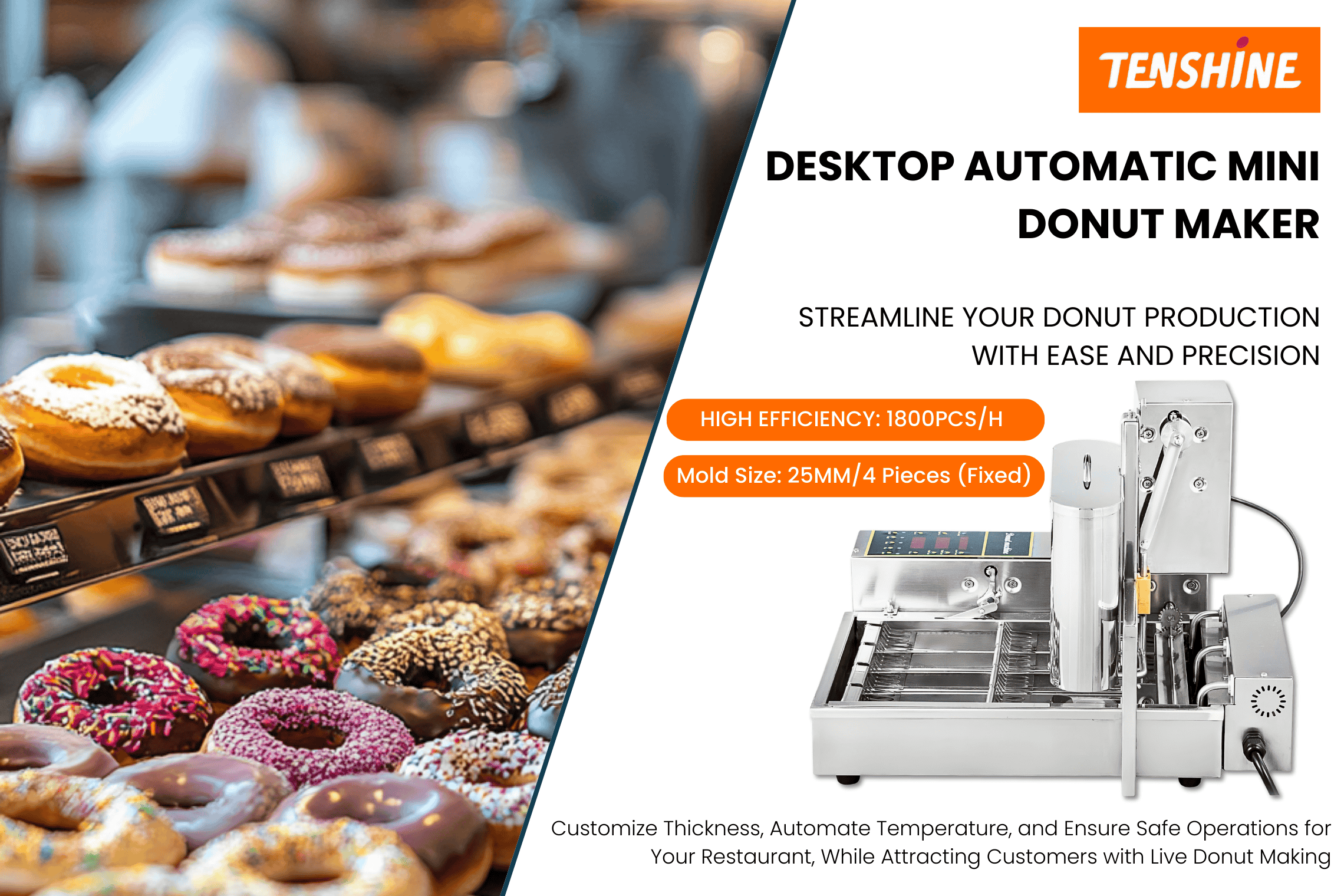

Turn High-Volume Mini Donuts into High Profits

Designed for food trucks, busy cafes, amusement parks, and catering events worldwide, the Tenshine LBD-4 (Electronic) is a fully automatic donut robot that does all the heavy lifting.

Forget manual frying. This 4-row powerhouse automates the forming, dropping, frying, flipping, and outputting process, capable of producing approximately 1,800 mini donuts per hour. It is the ultimate solution for businesses looking to serve fresh, hot donuts with minimal labor.

Why Choose the LBD-4 4-Row Model?

1. Massive Output (4-Row Efficiency)

Time is money during a rush. Unlike standard single-row machines, the LBD-4 features a wide hopper and oil tank design that processes 4 rows of mini donuts simultaneously.

- Yield: Approx. 1,800 pcs/hour.

- Donut Type: Perfect for high-margin "Mini Donuts" (20-40mm).

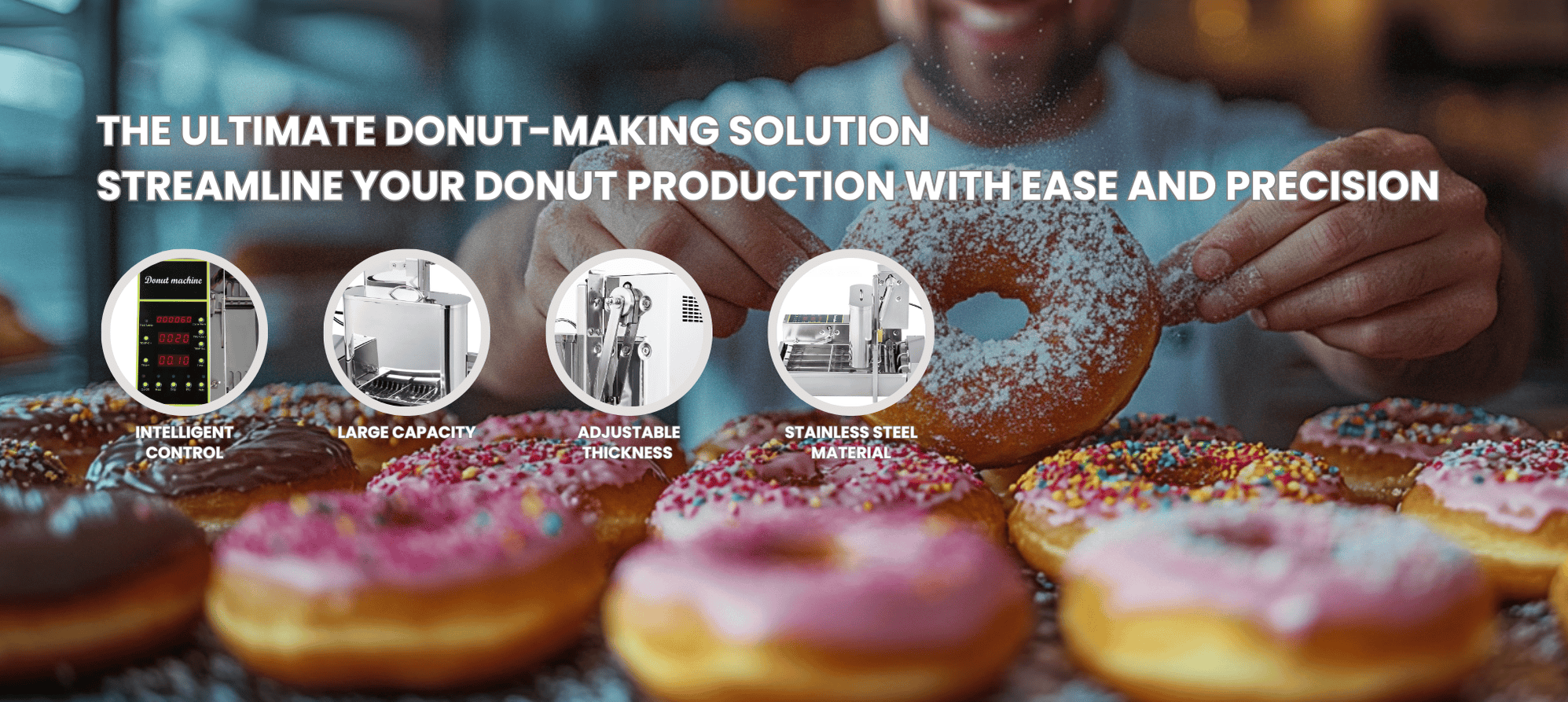

2. Intelligent Digital Control Panel

Consistency is key. The advanced electronic panel replaces old-fashioned manual knobs, giving you precise control over your production:

- Digital Thermostat: Maintains precise oil temperature for the perfect golden crisp.

- Timer Control: Adjust frying time to ensure dough is cooked through but never burnt.

- Integrated Counter: A 6-digit counter tracks your daily production, making inventory and sales tracking effortless.

3. "Set & Forget" Automation

Reduce staff costs. Once the hopper is filled and settings are dialed in, simply press "Auto". The machine handles the rest:

- Automatic Dropping: Precision forming plungers deposit dough perfectly.

- Automatic Flipping: The conveyor mechanism flips donuts to ensure even cooking on both sides.

- Automatic Output: Delivers cooked donuts directly to your receiving tray, ready for sugar or glazing.

4. 5-Level Thickness Adjustment

Customize your product. Use the adjustable knob on the depositor to choose from 5 different dough thickness levels. Whether you want light and airy or dense and cakey donuts, you have full control over the weight and texture.

5. Commercial Grade Build

Built to last in demanding commercial environments.

- Material: Constructed from high-quality 304 Stainless Steel for durability and rust resistance.

- Hygiene: The hopper, plunger, and conveyor system can be easily disassembled for thorough cleaning and sanitation.

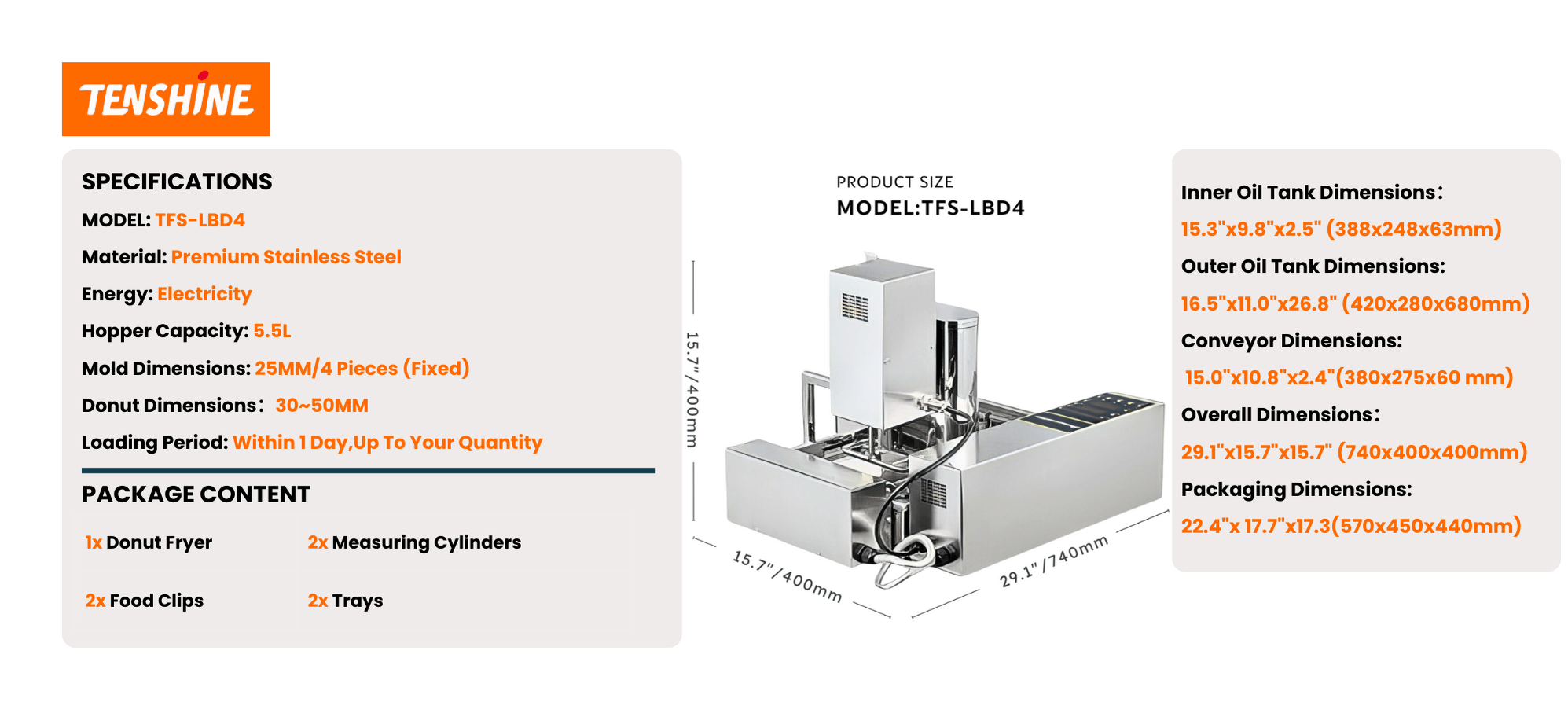

Technical Specifications

- Model: LBD-4 (Electronic Version)

- Voltage: 110V / 220V (Select upon order)

- Power: 2000W

- Hopper Capacity: Large 5.5L

- Machine Dimensions: 500 x 400 x 450 mm

- Net Weight: 16 kg

- Donut Diameter: 20mm - 40mm (Mini Donut Size)

- Rows: 4 Rows

❓ Frequently Asked Questions

Q: Can this machine make standard large donuts?

A: This specific LBD-4 model is optimized for Mini Donuts (4 rows) to maximize output speed (1,800/hr). The mold size creates donuts approximately 30-50mm in diameter after frying. If you need standard large donuts, please check our single-row or dual-row models.

Q: Is it suitable for a mobile food truck?

A: Absolutely. Its compact footprint ($500 \times 400 \times 450 \text{mm}$) and manageable weight (16kg) make it perfect for countertops in food trucks, concession trailers, and pop-up market stalls.

Q: Does it require special wiring?

A: The machine is rated at 2000W. It can typically run on a standard commercial circuit, but please ensure your power supply matches the voltage (110V or 220V) you select at checkout.

Q: Is it easy to clean?

A: Yes. The stainless steel construction wipes down easily. The main components like the hopper and plunger can be removed without tools for washing at the end of the day.